Cork flooring had its heyday in the 1970s, around the same time as Formica furniture! Now cork floors are making a comeback with the same undeniable benefits but with a new look! Indeed, Cork is now associated with more contemporary and aesthetic materials. It benefits from new technologies, which allow successful decorations on a material that no longer has to prove itself. They imitate the formats of parquet and laminate flooring and even modular PVC flooring.

Advantages of cork flooring

All-natural material

The first great advantage of Cork in this age of ecological and sustainable development is its entirely natural composition.

The material comes from the cork oak, a tree remarkable for its high bark production, which grows mainly in Portugal.

Good to know: only the bark of the cork oak is harvested. We harvest the bark every 9 years, the time of their regeneration. The trees regenerate without ever being cut down.

Ideal for renovation

Cork floors are often thin and ideal for interior renovation projects.

Traditional cork floors only require a little space.

The thickness ranges from 3 to 6 mm for glue-down cork floors.

A quiet floor

The disadvantage of some floor coverings is the noise when walking.

Cork absorbs the noise and gives a new acoustic comfort in footfall. No more clattering noise inside the room when walking, and comfort for the neighbours below!

Note: footfall noise is reduced by about 50% compared to a parquet or laminate floor installed as a floating floor, for example.

Natural thermal insulation

Cork is an ideal product for thermal insulation. The floor temperature is warm and remains stable regardless of the season.

Good to know: nothing to do with tiles, for example, a material strictly opposed to Cork in terms of heat!

Impact resistance

Cork is a compressed and very elastic material. Therefore, it is a flooring product that is resistant to impact and punching.

It resists well to falling objects, but also high heels!

Cork “parquet” floor

Product evolution

With today’s flooring technologies, Cork is a logical imitation of parquet. It is, after all, a wood base since we are talking about bark, so cork floor manufacturers have invested in manufacturing technologies derived from parquet.

The Cork is pressed onto a wood fibre base to become a floor covering similar to laminate or parquet flooring.

It can then be assembled with a click system and laid as a floating floor while retaining all the advantages of Cork. This is how a floor from yesterday became a floor of today!

Decoration

With its well-known “cork” appearance, Cork still exists and is still suitable for certain places in terms of decoration. But its aesthetics remains little modern.

Manufacturers have continued to innovate by working on the decorative aspect of Cork simply by pressing very effective and modern decorative papers directly on it. It’s like a parquet floor that can be stained or brushed, or laminated, which is only a photo that can be modified.

Note: the decorations are sometimes printed on a thin layer of real Cork; manufacturers print them directly.

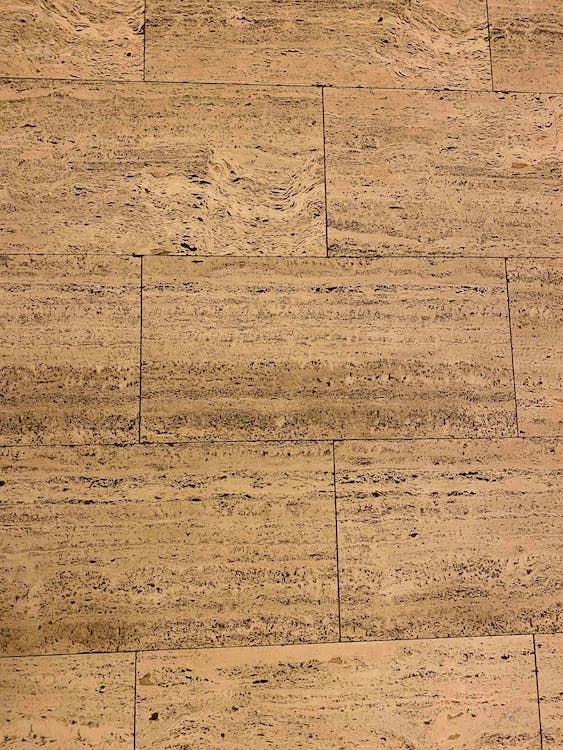

The result is easy-to-install cork flooring with designs that imitate all types of wood, for example, in many colours or even natural stone.

Resistance

The cork floors are then protected with special varnishes to achieve effective resistance according to the areas of use. This is their wear layer.

Other types of cork floors

Traditional cork flooring

Traditional cork floors are glued down. This thin version has been known for years, often in the form of tiles.

This version is ideal for renovations.

Cork and vinyl flooring

On the same multi-layer principle as for the imitation parquet, manufacturers also associate Cork and vinyl (PVC) for a successful floor covering in terms of decoration and stability. So we have both the decor and technicality of PVC and the advantages of cork material.

Good to know: thanks to this clever mix, we can obtain unique products compatible with wet rooms.

Cork as an underlay

The new cork products can also be integrated with the material underneath as an underlay for floating installation.

In short, Cork is above but also below: all advantages!

Formats and installation of cork floors

Cork floor formats

The thickness varies from 3/4 mm for traditional glue-down Cork and up to 12 mm for multilayer systems.

Cork floors exist as slabs or strips: slabs to imitate tiles with mineral decorations and strips to imitate parquet.

Here are some examples of formats:

– slabs: 400×600 mm;

– strips: 140/180×1200 mm.

Installation of cork floors

The initial manufacture of traditional cork flooring products requires a glued installation.

Thanks to the new multi-layer products, floating installation is now possible according to installation standards.

Note: time is saved, and the installation is less technical.

Price of cork flooring

For cork floors to be glued down for domestic use (mainly in tiles): between $42 and $49/m².

For multilayer cork floors for domestic use, floating installation: is approximately $50/m².